Soo dejiso Tilmaamaha iyo Cabbirka ugu dambeeyay ee iftiinka W.

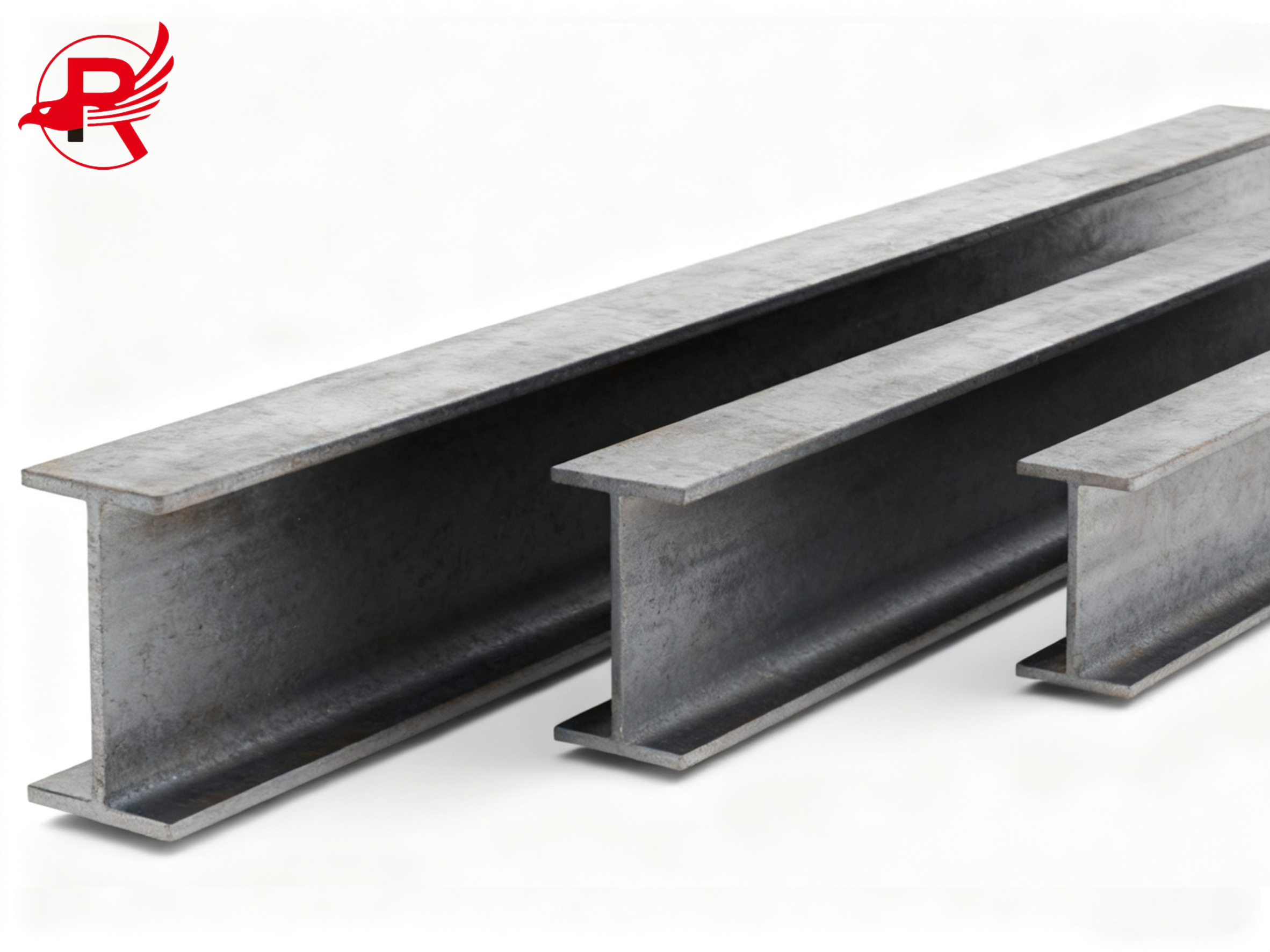

ASTM A36 Bir Qaab-Dhexe H ah | Bir Qaab-Dhexe oo Xoog Sare leh oo loogu talagalay Dhismaha | Cabbirro badan oo la heli karo

| Shay | Sharaxaad |

|---|---|

| Heerka Agabka | ASTM A36 |

| Xoogga Wax Soo Saarka | ≥345 MPa |

| Cabbirrada | W6×9, W8×10, W12×30, W14×43, iwm. |

| Dhererka | 6 m & 12 m ayaa kayd ah, dherer la habeeyey |

| Dulqaad | ASTM A6 / GB/T 11263 |

| Shahaadada | ISO 9001, kormeerka SGS / BV |

| Dusha sare | Kuleyl-kuleyl ah oo la galiyey, la rinjiyeeyay, ama la habeeyey |

| Codsiyada | Dhirta, bakhaarada, dhismayaasha, buundooyinka |

Xogta Farsamada

Qaab-dhismeedka Kiimikada ASTM A36 W-beam (ama H-beam)

| heerka birta | Kaarboon, | Manganese, | Fosfooraska, | baaruud, | Silikoon, | |

| ugu badnaan,% | % | ugu badnaan,% | ugu badnaan,% | % | ||

| A36 | 0.26 | -- | 0.04 | 0.05 | ≤0.40 | |

| FIIRO GAAR AH: Waxyaabaha ku jira naxaasta ayaa diyaar ah marka dalabkaaga la cayimo. | ||||||

Hantida Farsamada ASTM A36 W-beam (ama H-beam)

| Heerka Birta | Xoogga jiidista, ksi[MPa] | Dhibcaha wax soo saarka ugu yar, ksi[MPa] | Kordhinta 8 inji.[200] mm], ugu yaraan,% | Kordhinta 2 inji.[50] mm], ugu yaraan,% | |

| A36 | 58-80 [400-550] | 36[250] | 20.00 | 21 | |

Cabbirrada H-beam ee ASTM A36 ee ballaaran - W Beam

| Magacaabista | Cabbirrada | Halbeegyada Ma-guurtada ah | |||||||

| Daqiiqadda Inertia | Qaybta Modulus | ||||||||

| Imperial (oo ku jira x lb/ft) | Qoto dheer (gudaha) | Ballaca (in) | Dhumucyada Shabakadda (in) | Aagga Qaybaha (2) | Miisaanka (lb/ft) | Ix (4) | Iy (4) | Wx (3) | Wy (3) |

| W 27 x 178 | 27.8 | 14.09 | 0.725 | 52.3 | 178 | 6990 | 555 | 502 | 78.8 |

| W 27 x 161 | 27.6 | 14.02 | 0.660 | 47.4 | 161 | 6280 | 497 | 455 | 70.9 |

| W 27 x 146 | 27.4 | 14 | 0.605 | 42.9 | 146 | 5630 | 443 | 411 | 63.5 |

| W 27 x 114 | 27.3 | 10.07 | 0.570 | 33.5 | 114 | 4090 | 159 | 299 | 31.5 |

| W 27 x 102 | 27.1 | 10.02 | 0.515 | 30.0 | 102 | 3620 | 139 | 267 | 27.8 |

| W 27 x 94 | 26.9 | 10 | 0.490 | 27.7 | 94 | 3270 | 124 | 243 | 24.8 |

| W 27 x 84 | 26.7 | 9.96 | 0.460 | 24.8 | 84 | 2850 | 106 | 213 | 21.2 |

| W 24 x 162 | 25 | 13 | 0.705 | 47.7 | 162 | 5170 | 443 | 414 | 68.4 |

| W 24 x 146 | 24.7 | 12.9 | 0.650 | 43.0 | 146 | 4580 | 391 | 371 | 60.5 |

| W 24 x 131 | 24.5 | 12.9 | 0.605 | 38.5 | 131 | 4020 | 340 | 329 | 53.0 |

| W 24 x 117 | 24.3 | 12.8 | 0.55 | 34.4 | 117 | 3540 | 297 | 291 | 46.5 |

| W 24 x 104 | 24.1 | 12.75 | 0.500 | 30.6 | 104 | 3100 | 259 | 258 | 40.7 |

| W 24 x 94 | 24.1 | 9.07 | 0.515 | 27.7 | 94 | 2700 | 109 | 222 | 24.0 |

| W 24 x 84 | 24.1 | 9.02 | 0.470 | 24.7 | 84 | 2370 | 94.4 | 196 | 20.9 |

| W 24 x 76 | 23.9 | 9 | 0.440 | 22.4 | 76 | 2100 | 82.5 | 176 | 18.4 |

| W 24 x 68 | 23.7 | 8.97 | 0.415 | 20.1 | 68 | 1830 | 70.4 | 154 | 15.7 |

| W 24 x 62 | 23.7 | 7.04 | 0.430 | 18.2 | 62 | 1550 | 34.5 | 131 | 9.8 |

| W 24 x 55 | 23.6 | 7.01 | 0.395 | 16.2 | 55 | 1350 | 29.1 | 114 | 8.3 |

| W 21 x 147 | 22.1 | 12.51 | 0.720 | 43.2 | 147 | 3630 | 376 | 329 | 60.1 |

| W 21 x 132 | 21.8 | 12.44 | 0.650 | 38.8 | 132 | 3220 | 333 | 295 | 53.5 |

| W 21 x 122 | 21.7 | 12.39 | 0.600 | 35.9 | 122 | 2960 | 305 | 273 | 49.2 |

| W 21 x 111 | 21.5 | 12.34 | 0.550 | 32.7 | 111 | 2670 | 274 | 249 | 44.5 |

| W 21 x 101 | 21.4 | 12.29 | 0.500 | 29.8 | 101 | 2420 | 248 | 227 | 40.3 |

| W 21 x 93 | 21.6 | 8.42 | 0.580 | 27.3 | 93 | 2070 | 92.9 | 192 | 22.1 |

| W 21 x 83 | 21.4 | 8.36 | 0.515 | 24.3 | 83 | 1830 | 81.4 | 171 | 19.5 |

| W 21 x 73 | 21.2 | 8.3 | 0.455 | 21.5 | 73 | 1600 | 70.6 | 151 | 17.0 |

| W 21 x 68 | 21.1 | 8.27 | 0.430 | 20.0 | 68 | 1480 | 64.7 | 140 | 15.7 |

| W 21 x 62 | 21 | 8.24 | 0.400 | 18.3 | 62 | 1330 | 57.5 | 127 | 13.9 |

| W 21 x 57 | 21.1 | 6.56 | 0.405 | 16.7 | 57 | 1170 | 30.6 | 111 | 9.4 |

| W 21 x 50 | 20.8 | 6.53 | 0.380 | 14.7 | 50 | 984 | 24.9 | 94.5 | 7.6 |

| W 21 x 44 | 20.7 | 6.5 | 0.350 | 13.0 | 44 | 843 | 20.7 | 81.6 | 6.4 |

Guji badhanka ku yaal Midig

| Cabbirka | Baaxadda Caadiga ah | Dulqaadka (ASTM A6/A6M) | Qoraallo |

|---|---|---|---|

| Dhererka H | 100–600 mm | ±3 mm | Waxaa loo habeyn karaa codsi kasta oo macaamiisha ah |

| Ballaca Flange-ka B | 100–300 mm | ±3 mm | — |

| Dhumucda shabakadda t_w | 6–16 mm | ±10% ama ±1 mm | Qiimo weyn ayaa khuseeya |

| Dhumucda Flange-ka t_f | 8–25 mm | ±10% ama ±1 mm | Qiimo weyn ayaa khuseeya |

| Dhererka L | 6–12 mitir | ±12 mm (6 m), ±24 mm (12 m) | La hagaajin karo qandaraas kasta |

| Nooca Habaynta | Xulashooyinka | Sharaxaad / Kala Duwan | Tirada Dalabka Ugu Yar (MOQ) |

|---|---|---|---|

| Cabbirka | Dhererka (H), Ballaca Flange-ka (B), Dhumucda Shabakadu (t_w), Dhumucda Flange-ka (t_f), Dhererka (L) | H: 100–600 mm; B: 100–300 mm; t_w: 6–16 mm; t_f: 8–25 mm; Dhererka la jaray iyadoo loo eegayo shuruudaha | 20 tan |

| Habaynta | Qoditaanka, Goynta Godka, Habaynta Dhammaadka, Alxanka Hore Loo Sameeyay | Waxaa loo farsameyn karaa sida loogu baahdo mashruuca; dhammaadka waxaa loo jari karaa, la jeexi karaa, ama lagu dhejin karaa qaab-dhismeedyo | 20 tan |

| Daaweynta Dusha Sare | Dahaarka Kulul ee Galvanizing-ka, Dahaarka Ka-hortagga Daxalka (Rinji / Epoxy), Bacriminta Ciidda, Dusha Siman | Dooro daawaynta iska caabbinta daxalka, ilaalinta miridhku, ama dhammaystirka caadiga ah | 20 tan |

| Calaamadaynta iyo Baakaynta | Calaamadaynta Gaarka ah, Habka Gaadiidka | Lambarka mashruuca ama qaabka la calaamadeeyay; baakad loogu talagalay rarista weelka ama baakadaha | 20 tan |

Dusha Caadiga ah

Dusha sare ee galvanized (qalooca galvanizing-kulka kulul ≥ 85μm, cimriga adeegga ilaa 15-20 sano),

Dusha sare ee Saliidda Madow

Dhismaha: Waxay u adeegtaa sidii alwaax qaabaysan iyo tiir iyo xafiis dabaq sare ah, dabaq, suuq wax laga iibsado iyo dhisme kale oo dhisme; sidoo kale waxaa loo isticmaalaa dhismaha warshadda warshadaha iyo alwaaxda wiishka.

Codsiyada Buundada: Waxaa loo isticmaalaa buundooyinka waaweyn ee yar yar iyo kuwa dhexe iyo kuwa tareenka ee nidaamka sagxadaha iyo qaab-dhismeedka hoose.

Qaab-dhismeedyada Dowladda Hoose iyo Gaarka ah: Waxaa loo shaqeeyaa saldhigyada tareenka dhulka hoostiisa mara, kuwa qaada dhuumaha magaalada, saldhigyada wiishashka munaaradaha, iyo shaqada dhismaha ee ku meel gaarka ah.

Taageerada Warshadda Warshadaha: Laydhka taageerada toosan waa qayb muhiim u ah xasilloonida, taas oo kor u qaadaysa qaab-dhismeedka dhismaha warshadaha iyadoo bixinaysa xasillooni labada diyaaradood ee toosan iyo kuwa toosan.

1) Xafiiska Laanta - Taageerada ku hadasha luqadda Isbaanishka, kaalmada nadiifinta kastamka, iwm.

2) In ka badan 5,000 oo tan oo kayd ah ayaa ku jira kaydka, oo leh cabbirro kala duwan

3) Waxaa baaraya hay'ado awood leh sida CCIC, SGS, BV, iyo TUV, iyadoo la adeegsanayo baakado caadi ah oo badda ku habboon.

Baakad:

-

Ilaalinta Aasaasiga ah:Xirmooyin lagu duubay maro dahaadh ah oo leh 2-3 baakadood oo biyo-mareen ah; oo lagu daboolay maro roobka u adkaysata kulaylka.

-

Isku-xidhka:Waxaa lagu xiray suuman bir ah oo 12–16 mm ah, oo la jaanqaadaya qalabka qaadista 2–3 tan ee dekedaha Mareykanka.

-

Calaamadaynta:Calaamadaha laba-luqadlaha ah (Ingiriis + Isbaanish) oo muujinaya agabka, qeexitaannada, koodhka HS, lambarka dufcadda, iyo warbixinta imtixaanka.

Ikhtiyaarada Bixinta:

-

Gaadiidka Waddooyinka:Ku habboon masaafada gaaban ama gaarsiinta tooska ah goobaha; gawaarida xamuulka ah oo lagu qalabeeyay cabbiraadaha ka hortagga simbiriirixanka.

-

Gaadiidka Tareenka:Kharash ahaan u habboon shixnadaha masaafada dheer iyo kuwa aadka u badan.

-

Gaadiidka Badda:Ku habboon dhoofinta caalamiga ah; waxay taageertaa rarista weelasha badan ama kuwa sare ee furan ee alaabada dhaadheer.

-

Biyo-mareenka Gudaha/Deegaanka:Ku habboon dhaqaajinta alwaaxyada waaweyn ee H-ga ee ku teedsan webiyada ama marinnada biyaha ee gudaha.

-

Gaadiidka Gaarka ah:Alwaaxyo waaweyn ama miisaan culus leh oo lagu raro jiidayaal sariiro hoose oo badan leh ama jiidayaal isku dhafan.

Xalka Gaadiidka Suuqa Ameerika: ASTM I Beams waxaa ugu horreyn loo dhoofiyaa Ameerika iyada oo loo marayo xamuulka badda ee konteenarrada ku jira oo leh xarig bir ah, ilaalin dhammaadka, iyo daaweyn ikhtiyaari ah oo ka hortagga miridhku si loo hubiyo gaadiid badbaado leh oo hufan.

S: Heerkee ayay H-beam-kaagu u hoggaansamaan wadamada Bartamaha Ameerika?

A: Shaashaddayada h waxay xaqiijinaysaa astm a36 iyo a572 darajada 50 kaas oo si weyn looga isticmaalo bartamaha Ameerika. Waxaan sidoo kale bixinnaa shaabadda caadiga ah ee maxalliga ah sida NOM ee Mexico.

S: Imisa ayay qaadanaysaa wakhtiga keenista Panama?

J: Xamuulka badda ee ka yimaada Dekadda Tianjin una socda Panama/Colon Free Trade Zone wuxuu caadi ahaan qaataa 28-32 maalmood. Qiyaastii 45-60 maalmood oo keenis ah oo ay ku jiraan wax soo saarka iyo nadiifinta kastamka. Maraakiibta degdega ah ayaa diyaar ah.

S: Ma ka caawisaa nadiifinta kastamka?

J: Haa, waxaan leenahay dilaaliin xirfadlayaal ah oo ku sugan bartamaha Ameerika si ay u daryeelaan ogeysiisyada, canshuuraha, iyo waxaas oo dhan, si gaarsiintaadu u noqoto mid habsami leh oo waqtigeeda ku habboon.

Cinwaanka

Bl20, Shanghecheng, Shuangjie Street, Degmada Beichen, Tianjin, Shiinaha

Iimayl

Telefoon

+86 13652091506