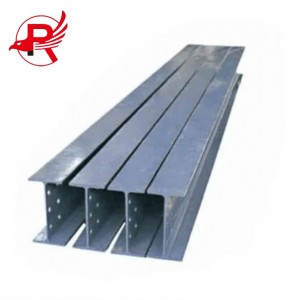

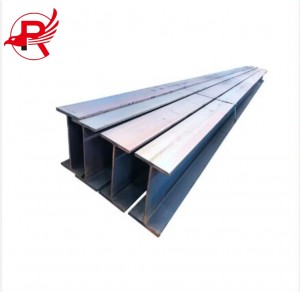

Dhismaha Birta Qaabaysan ee EN H h

H-beerBirta si weyn ayaa loo isticmaalaa, inta badan waxaa loo isticmaalaa: noocyo kala duwan oo dhismeyaal madani ah iyo kuwo warshadeed; Noocyo kala duwan oo warshado ah oo muddo dheer socda iyo dhismayaal dhaadheer oo casri ah, gaar ahaan meelaha ay ka jiraan dhaqdhaqaaqyo dhulgariir oo soo noqnoqda iyo xaalado shaqo oo heerkul sare leh; Buundooyin waaweyn oo leh awood qaadis weyn, xasillooni wanaagsan oo isgoys ah iyo baaxad weyn ayaa loo baahan yahay; Qalab culus; Waddo weyn; Qalfoofka maraakiibta; Taageerada macdanta; Daaweynta aasaaska iyo injineernimada biyo-xidheenka; Qaybo kala duwan oo mashiinka ah.

HABKA SOO SAARKA ALAABTA

Flange-kaH lightwaa barbar socda ama ku dhawaad isku mid ah gudaha iyo dibadda, dhammaadka flange-kuna wuxuu ku yaal xagal midig, sidaa darteed waxaa loogu yeeraa flange I-steel oo barbar socda. Dhumucda shabagga birta qaab H ah ayaa ka yar tan I-teel caadiga ah oo leh dherer isku mid ah shabakadda, ballaca flange-kuna wuxuu ka weyn yahay tan I-teel caadiga ah oo leh dherer isku mid ah shabakadda, sidaas darteed waxaa sidoo kale loogu yeeraa I-teel ballaaran. Marka loo eego qaabka, modules-ka qaybta, daqiiqadda inertia iyo xoogga u dhigma ee H-teel ayaa si cad uga wanaagsan kan I-teel caadiga ah oo leh miisaan isku mid ah. Loo isticmaalo shuruudaha kala duwan ee qaab-dhismeedka birta, ha ahaato mid hoos u foorarsan, culayska cadaadiska, culayska aan caadiga ahayn wuxuu muujinayaa waxqabadkiisa sare, wuxuu si weyn u hagaajin karaa awoodda qaadista marka loo eego I-teel caadiga ah, isagoo badbaadinaya birta 10% ~ 40%. Birta qaab H ah waxay leedahay flange ballaaran, shabakad khafiif ah, qeexitaanno badan, iyo isticmaal dabacsan, taas oo badbaadin karta 15% ilaa 20% birta qaab-dhismeedyada kala duwan ee truss. Maadaama flange-keedu uu is barbar yaallo gudaha iyo dibaddaba, dhammaadka geeskuna uu ku yaal xagal sax ah, way fududahay in la isku daro oo la isku daro qaybo kala duwan, kuwaas oo badbaadin kara qiyaastii 25% culeyska shaqada ee alxanka iyo riveting-ka, waxayna si weyn u dedejin kartaa xawaaraha dhismaha mashruuca waxayna gaabin kartaa muddada dhismaha.

CABBIRKA ALAABTA

| Magacaabista | Unt Miisaanka kg/m) | Qaybta Caadiga ah sawir mm | Qaybaha Ama (cm²) | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE28 | AA | 61.3 | 264.0 | 280.0 | 7.0 | 10.0 | 24.0 | 78.02 |

| A | 76.4 | 270.0 | 280.0 | 80 | 13.0 | 24.0 | 97.26 | |

| B | 103 | 280.0 | 280.0 | 10.5 | 18.0 | 24.0 | 131.4 | |

| M | 189 | 310.0 | 288.0 | 18.5 | 33.0 | 24.0 | 240.2 | |

| HE300 | AA | 69.8 | 283.0 | 300.0 | 7.5 | 10.5 | 27.0 | 88.91 |

| A | 88.3 | 200.0 | 300.0 | 85 | 14.0 | 27.0 | 112.5 | |

| B | 117 | 300.0 | 300.0 | 11.0 | 19.0 | 27.0 | 149.1 | |

| M | 238 | 340.0 | 310.0 | 21.0 | 39.0 | 27.0 | 303.1 | |

| HE320 | AA | 74.3 | 301.0 | 300.0 | 80 | 11.0 | 27.0 | 94.58 |

| A | 97.7 | 310.0 | 300.0 | 9.0 | 15.5 | 27.0 | 124.4 | |

| B | 127 | 320.0 | 300.0 | 11.5 | 20.5 | 27.0 | 161.3 | |

| M | 245 | 359.0 | 309.0 | 21.0 | 40.0 | 27.0 | 312.0 | |

| HE340 | AA | 78.9 | 320.0 | 300.0 | 85 | 11.5 | 27.0 | 100.5 |

| A | 105 | 330.0 | 300.0 | 9.5 | 16.5 | 27.0 | 133.5 | |

| B | 134 | 340.0 | 300.0 | 12.0 | 21.5 | 27.0 | 170.9 | |

| M | 248 | 377.0 | 309.0 | 21.0 | 40.0 | 27.0 | 315.8 | |

| HE360 | AA | 83.7 | 339.0 | 300.0 | 9.0 | t2.0 | 27.0 | 106.6 |

| A | 112 | 350.0 | 300.0 | 10.0 | 17.5 | 27.0 | 142.8 | |

| B | 142 | 360.0 | 300.0 | 12.5 | 22.5 | 27.0 | 180.6 | |

| M | 250 | 395.0 | 308.0 | 21.0 | 40.0 | 27.0 | 318.8 | |

| HE400 | AA | 92.4 | 3780 | 300.0 | 9.5 | 13.0 | 27.0 | 117.7 |

| A | 125 | 390.0 | 300.0 | 11.0 | 19.0 | 27.0 | 159.0 | |

| B | 155 | 400.0 | 300.0 | 13.5 | 24.0 | 27.0 | 197.8 | |

| M | 256 | 4320 | 307.0 | 21.0 | 40.0 | 27.0 | 325.8 | |

| HE450 | AA | 99.8 | 425.0 | 300.0 | 10.0 | 13.5 | 27.0 | 127.1 |

| A | 140 | 440.0 | 300.0 | 11.5 | 21.0 | 27.0 | 178.0 | |

| B | 171 | 450.0 | 300.0 | 14.0 | 26.0 | 27.0 | 218.0 | |

| M | 263 | 4780 | 307.0 | 21.0 | 40.0 | 27.0 | 335.4 | |

| Magacaabista | Cutubka Miisaanka kg/m) | Qaybta Caadiga ah Cabbirka (mm) | Qaybta Aagga (cm²) | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE50 | AA | 107 | 472.0 | 300.0 | 10.5 | 14.0 | 27.0 | 136.9 |

| A | 155 | 490.0 | 300.0 | t2.0 | 23.0 | 27.0 | 197.5 | |

| B | 187 | 500.0 | 300.0 | 14.5 | 28.0 | 27.0 | 238.6 | |

| M | 270 | 524.0 | 306.0 | 21.0 | 40.0 | 27.0 | 344.3 | |

| HE550 | AA | t20 | 522.0 | 300.0 | 11.5 | 15.0 | 27.0 | 152.8 |

| A | 166 | 540.0 | 300.0 | t2.5 | 24.0 | 27.0 | 211.8 | |

| B | 199 | 550.0 | 300.0 | 15.0 | 29.0 | 27.0 | 254.1 | |

| M | 278 | 572.0 | 306.0 | 21.0 | 40.0 | 27.0 | 354.4 | |

| HE60 | AA | t29 | 571.0 | 300.0 | t2.0 | 15.5 | 27.0 | 164.1 |

| A | 178 | 500.0 | 300.0 | 13.0 | 25.0 | 27.0 | 226.5 | |

| B | 212 | 600.0 | 300.0 | 15.5 | 30.0 | 27.0 | 270.0 | |

| M | 286 | 620.0 | 305.0 | 21.0 | 40.0 | 27.0 | 363.7 | |

| HE650 | AA | 138 | 620.0 | 300.0 | t2.5 | 16.0 | 27.0 | 175.8 |

| A | 190 | 640.0 | 300.0 | t3.5 | 26.0 | 27.0 | 241.6 | |

| B | 225 | 660.0 | 300.0 | 16.0 | 31.0 | 27.0 | 286.3 | |

| M | 293 | 668.0 | 305.0 | 21.0 | 40.0 | 27.0 | 373.7 | |

| HE700 | AA | 150 | 670.0 | 300.0 | 13.0 | 17.0 | 27.0 | 190.9 |

| A | 204 | 600.0 | 300.0 | 14.5 | 27.0 | 27.0 | 260.5 | |

| B | 241 | 700.0 | 300.0 | 17.0 | 32.0 | 27.0 | 306.4 | |

| M | 301 | 716.0 | 304.0 | 21.0 | 40.0 | 27.0 | 383.0 | |

| HE800 | AA | 172 | 770.0 | 300.0 | 14.0 | 18.0 | 30.0 | 218.5 |

| A | 224 | 790.0 | 300.0 | 15.0 | 28.0 | 30.0 | 285.8 | |

| B | 262 | 800.0 | 300.0 | 17.5 | 33.0 | 30.0 | 334.2 | |

| M | 317 | 814.0 | 303.0 | 21.0 | 40.0 | 30.0 | 404.3 | |

| HE800 | AA | 198 | 870.0 | 300.0 | 15.0 | 20.0 | 30.0 | 252.2 |

| A | 252 | 800.0 | 300.0 | 16.0 | 30.0 | 30.0 | 320.5 | |

| B | 291 | 900.0 | 300.0 | 18.5 | 35.0 | 30.0 | 371.3 | |

| M | 333 | 910.0 | 302.0 | 21.0 | 40.0 | 30.0 | 423.6 | |

| HEB1000 | AA | 222 | 970.0 | 300.0 | 16.0 | 21.0 | 30.0 | 282.2 |

| A | 272 | 0.0 | 300.0 | 16.5 | 31.0 | 30.0 | 346.8 | |

| B | 314 | 1000.0 | 300.0 | 19.0 | 36.0 | 30.0 | 400.0 | |

| M | 349 | 1008 | 302.0 | 21.0 | 40.0 | 30.0 | 444.2 | |

ENH- Bir qaabaysan

Darajada: EN10034:1997 EN10163-3:2004

Faahfaahinta: HEA HEB iyo HEM

Heerka: EN

ASTAAMAHA

Waxaa jira tilmaamo badan oo ku saabsan badeecadahaH-beer, hababka kala soociddana waa sidan soo socota.(1) Sida ku cad ballaca flange-ka ee badeecada, waxaa loo qaybiyaa flange ballaaran, flange dhexe iyo flange cidhiidhi ah H-beam. Ballaca flange-ka B ee flange ballaaran iyo flange dhexe H-beam wuxuu ka weyn yahay ama la mid yahay dhererka shabakadda H. Ballaca flange-ka B ee flange cidhiidhi ah birta qaabka H waxay la mid tahay qiyaastii kala bar dhererka H ee saxanka shabakadda.(2) Sida ku cad isticmaalka badeecada, waxaa loo qaybiyaa dogob bir ah nooca H, tiir bir ah nooca H, tuul bir ah nooca H iyo dogob bir ah nooca H oo leh flange aad u qaro weyn. Mararka qaarkood birta kanaalka lugta ee barbar socda iyo birta T-beam ee barbar socda ayaa sidoo kale lagu daraa noocyada H-beam. Guud ahaan, birta H-beam ee cidhiidhiga ah waxaa loo isticmaalaa dogob iyo flange ballaaran H-beam bir ah ayaa loo isticmaalaa tiir ahaan. Sidaas darteed, waxaa sidoo kale loo yaqaan birta H-beam ee birta iyo tiir H-beam bir ah. (3) Sida ku cad habka wax soo saarka, waxaa loo qaybiyaa birta H-beam ee la alxan iyo birta H-beam ee la duubay. (4) Sida ku cad qeexitaanka cabbirka, waxaa loo qaybiyaa bir weyn, dhexdhexaad ah iyo mid yar oo qaab H ah. Guud ahaan, alaabada leh dhererka shabakadda H oo ka sarreeya 700mm waxaa loo yaqaan weyn, 300 ~ 700mm waxaa loo yaqaan dhexdhexaad, kuwa ka yar 300mm waxaa loo yaqaan yar. Dhammaadka 1990, dhererka shabakadda H-beam ee ugu weyn adduunka oo ah 1200mm, ballac flange ah oo ah 530mm.

BAARITAANKA ALAABTA

Shuruudaha baaritaanka birta qaabka H waxaa inta badan ka mid ah dhinacyada soo socda:

Tayada muuqaalka: Tayada muuqaalka birta qaab-H ah waa inay u hoggaansantaa heerarka khuseeya iyo shuruudaha kala-soocidda. Dusha sare waa inay ahaataa mid siman oo siman, iyada oo aan lahayn godad muuqda, xoqan, miridhku iyo cillado kale.

Cabbirrada Joomatari: Dhererka, ballaca, dhererka, dhumucda shabakadda, dhumucda flange-ka iyo cabbirrada kale ee birta qaab-H ah waa inay u hoggaansamaan heerarka khuseeya iyo shuruudaha kala-hormarinta.

Qallooca: Qallooca birta qaabka H waa inuu waafaqsanaadaa heerarka khuseeya iyo shuruudaha kala horraysiinta. Waxaa lagu ogaan karaa iyadoo la cabbirayo in diyaaradaha labada daraf ee birta qaabka H ay is barbar socdaan ama la isticmaalayo mitir qalloocan.

Maroojin: Maroojinka birta qaab H ah waa inuu waafaqsanaadaa heerarka khuseeya iyo shuruudaha kala horraysiinta. Waxaa lagu ogaan karaa iyadoo la cabbirayo in dhinaca birta qaab H ah uu toosan yahay ama uu leeyahay mitir maroojin ah.

Kala leexashada miisaanka: Miisaanka birta qaabka H waa inuu u hoggaansamaa heerarka khuseeya iyo shuruudaha kala horraysiinta. Kala leexashada miisaanka waxaa lagu ogaan karaa miisaan.

Halabuurka Kiimikada: Haddii birta qaab-H ah loo baahan yahay in la alxamo ama si kale loo farsameeyo, halabuurka kiimikadeedu waa inuu u hoggaansamo heerarka khuseeya iyo shuruudaha kala horraysiinta.

Sifooyinka farsamada: Sifooyinka farsamada ee birta qaabka H waa inay u hoggaansamaan heerarka khuseeya iyo shuruudaha kala horraysiinta, oo ay ku jiraan xoogga la riixo, barta wax soo saarka, dheereynta iyo tilmaamayaasha kale.

Tijaabin aan burburin: Haddii birta qaab-dhismeedka H u baahan tahay tijaabin aan burburin, waa in lagu tijaabiyaa iyadoo la raacayo heerarka khuseeya iyo shuruudaha kala-hormarinta si loo hubiyo in tayadeeda gudaha ay wanaagsan tahay.

Baakadeynta iyo calaamadeynta: Baakadeynta iyo calaamadeynta birta qaabka H waa inay u hoggaansantaa heerarka khuseeya iyo shuruudaha dalbashada si loo fududeeyo rarista iyo kaydinta.

Marka la soo koobo, shuruudaha kor ku xusan waa in si buuxda loo tixgeliyaa marka la baarayo birta qaabka H si loo hubiyo in tayadeedu ay buuxiso heerarka khuseeya iyo shuruudaha dalbashada, iyo in la siiyo dadka isticmaala alaabada birta qaabka H ugu fiican.

Codsiga

Caadi ahH-beerQalabka birta waxaa ka mid ah Q235B, SM490, SS400, Q345 iyo Q345B. Halabuurka kiimikada iyo sifooyinka farsamada ee agabkan way kala duwan yihiin, marka marka la dooranayo isticmaalka H-beam, waxaa lagama maarmaan ah in la doorto agabka ku habboon iyadoo loo eegayo xaaladda gaarka ah.

BAAKADAHA IYO GEYNTA

Baakad iyo ilaalin:

Baakaduhu waxay door muhiim ah ka ciyaaraan ilaalinta tayada ASTM A36H lightbirta inta lagu jiro rarista iyo kaydinta. Agabka waa in si ammaan ah loogu xidhaa, iyadoo la isticmaalayo suunno ama xargaha xoogga badan si looga hortago dhaqdhaqaaqa iyo waxyeelada iman karta. Intaa waxaa dheer, waa in la qaadaa tallaabooyin lagu ilaalinayo birta ka ilaalinta qoyaanka, boodhka, iyo arrimaha kale ee deegaanka. Ku duubista xirmooyinka walxo u adkaysta cimilada, sida balaastig ama maro aan biyuhu celin, waxay ka caawisaa ilaalinta daxalka iyo miridhku.

Su'aalaha Badiya La Weydiiyo

1. Sideen kaaga heli karaa xigasho?

Waad noo dhaafi kartaa farriin, waxaanan ka jawaabi doonnaa farriin kasta waqtigeeda.

2. Ma alaabta ku geyn doontaa waqtigii loogu talagalay?

Haa, waxaan ballan qaadaynaa inaan bixinno alaabada ugu tayada wanaagsan iyo gaarsiinta waqtigii loogu talagalay. Daacadnimadu waa mabda'a shirkaddayada.

3. Ma heli karaa muunado ka hor dalabka?

Haa, dabcan. Badanaa muunadahayagu waa bilaash, waxaan ku soo saari karnaa muunadahaaga ama sawirrada farsamada.

4. Waa maxay shuruudaha lacag bixintaada?

Muddada lacag bixinta ee caadiga ah waa 30% deebaaji, waxaana naga xiga B/L. EXW, FOB, CFR, iyo CIF.

5. Ma aqbashaa kormeerka dhinac saddexaad?

Haa runtii waan aqbalnaa.

6. Sideen ugu kalsoonahay shirkaddaada?

Waxaan ku takhasusnay ganacsiga birta sannado badan annagoo ah alaab-qeybiye dahab ah, xaruntiisuna waxay ku taal gobolka Tianjin, waanu soo dhaweyneynaa inaan si kasta u baarno.