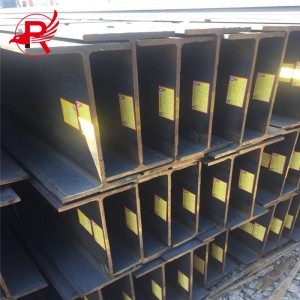

Tayada Sare h16 x 101 150x150x7x10 Q235 Q345b Biro Duuban oo kulul oo IPE HEA HEB EN H-Qaabadaysan

HABKA SOO SAARKA ALAABTA

Tilmaamahani waxay tilmaamayaan noocyo kala duwan ooKu salaysan iftiinka IPEcabbirkooda iyo sifooyinkooda:

- HEQaybaha birta (IPN): Kuwani waa alwaax bir ah oo qaab I ah oo leh flanges ballaaran iyo shabakado qaro weyn, oo ku habboon codsiyada qaab-dhismeedka ee u baahan awood culays-qaadis oo sare.

- HEBQaybaha birta (IPB): Kuwani waa alwaax bir ah oo qaab I ah oo leh ballaca iyo dhumucda flange dhexdhexaad ah, oo si caadi ah loogu isticmaalo qaab-dhismeedka dhismaha kala duwan.

- Qaybaha birta ee nooca HEM-ka ah: Kuwani waa qaybo bir ah oo I-beam ah oo leh dherer flange oo weyn iyo ballaca flange oo yar, taasoo keenta xoog sare iyo awood culays qaadis. Noocyada kala duwan ee qaybaha birta ah waxay leeyihiin astaamo u gaar ah oo naqshadaynta qaab-dhismeedka ah; sidaa darteed, mashaariicda injineernimada gaarka ah, nooca ku habboon waa in lagu xushaa iyadoo lagu saleynayo shuruudaha dhabta ah.

CABBIRKA ALAABTA

| Magacaabista | Unt Miisaanka kg/m) | Qaybta Caadiga ah sawir mm | Qaybaha Ama (cm²) | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE28 | AA | 61.3 | 264.0 | 280.0 | 7.0 | 10.0 | 24.0 | 78.02 |

| A | 76.4 | 270.0 | 280.0 | 80 | 13.0 | 24.0 | 97.26 | |

| B | 103 | 280.0 | 280.0 | 10.5 | 18.0 | 24.0 | 131.4 | |

| M | 189 | 310.0 | 288.0 | 18.5 | 33.0 | 24.0 | 240.2 | |

| HE300 | AA | 69.8 | 283.0 | 300.0 | 7.5 | 10.5 | 27.0 | 88.91 |

| A | 88.3 | 200.0 | 300.0 | 85 | 14.0 | 27.0 | 112.5 | |

| B | 117 | 300.0 | 300.0 | 11.0 | 19.0 | 27.0 | 149.1 | |

| M | 238 | 340.0 | 310.0 | 21.0 | 39.0 | 27.0 | 303.1 | |

| HE320 | AA | 74.3 | 301.0 | 300.0 | 80 | 11.0 | 27.0 | 94.58 |

| A | 97.7 | 310.0 | 300.0 | 9.0 | 15.5 | 27.0 | 124.4 | |

| B | 127 | 320.0 | 300.0 | 11.5 | 20.5 | 27.0 | 161.3 | |

| M | 245 | 359.0 | 309.0 | 21.0 | 40.0 | 27.0 | 312.0 | |

| HE340 | AA | 78.9 | 320.0 | 300.0 | 85 | 11.5 | 27.0 | 100.5 |

| A | 105 | 330.0 | 300.0 | 9.5 | 16.5 | 27.0 | 133.5 | |

| B | 134 | 340.0 | 300.0 | 12.0 | 21.5 | 27.0 | 170.9 | |

| M | 248 | 377.0 | 309.0 | 21.0 | 40.0 | 27.0 | 315.8 | |

| HE360 | AA | 83.7 | 339.0 | 300.0 | 9.0 | t2.0 | 27.0 | 106.6 |

| A | 112 | 350.0 | 300.0 | 10.0 | 17.5 | 27.0 | 142.8 | |

| B | 142 | 360.0 | 300.0 | 12.5 | 22.5 | 27.0 | 180.6 | |

| M | 250 | 395.0 | 308.0 | 21.0 | 40.0 | 27.0 | 318.8 | |

| HE400 | AA | 92.4 | 3780 | 300.0 | 9.5 | 13.0 | 27.0 | 117.7 |

| A | 125 | 390.0 | 300.0 | 11.0 | 19.0 | 27.0 | 159.0 | |

| B | 155 | 400.0 | 300.0 | 13.5 | 24.0 | 27.0 | 197.8 | |

| M | 256 | 4320 | 307.0 | 21.0 | 40.0 | 27.0 | 325.8 | |

| HE450 | AA | 99.8 | 425.0 | 300.0 | 10.0 | 13.5 | 27.0 | 127.1 |

| A | 140 | 440.0 | 300.0 | 11.5 | 21.0 | 27.0 | 178.0 | |

| B | 171 | 450.0 | 300.0 | 14.0 | 26.0 | 27.0 | 218.0 | |

| M | 263 | 4780 | 307.0 | 21.0 | 40.0 | 27.0 | 335.4 | |

| Magacaabista | Cutubka Miisaanka kg/m) | Qaybta Caadiga ah Cabbirka (mm) | Qaybta Aagga (cm²) | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE50 | AA | 107 | 472.0 | 300.0 | 10.5 | 14.0 | 27.0 | 136.9 |

| A | 155 | 490.0 | 300.0 | t2.0 | 23.0 | 27.0 | 197.5 | |

| B | 187 | 500.0 | 300.0 | 14.5 | 28.0 | 27.0 | 238.6 | |

| M | 270 | 524.0 | 306.0 | 21.0 | 40.0 | 27.0 | 344.3 | |

| HE550 | AA | t20 | 522.0 | 300.0 | 11.5 | 15.0 | 27.0 | 152.8 |

| A | 166 | 540.0 | 300.0 | t2.5 | 24.0 | 27.0 | 211.8 | |

| B | 199 | 550.0 | 300.0 | 15.0 | 29.0 | 27.0 | 254.1 | |

| M | 278 | 572.0 | 306.0 | 21.0 | 40.0 | 27.0 | 354.4 | |

| HE60 | AA | t29 | 571.0 | 300.0 | t2.0 | 15.5 | 27.0 | 164.1 |

| A | 178 | 500.0 | 300.0 | 13.0 | 25.0 | 27.0 | 226.5 | |

| B | 212 | 600.0 | 300.0 | 15.5 | 30.0 | 27.0 | 270.0 | |

| M | 286 | 620.0 | 305.0 | 21.0 | 40.0 | 27.0 | 363.7 | |

| HE650 | AA | 138 | 620.0 | 300.0 | t2.5 | 16.0 | 27.0 | 175.8 |

| A | 190 | 640.0 | 300.0 | t3.5 | 26.0 | 27.0 | 241.6 | |

| B | 225 | 660.0 | 300.0 | 16.0 | 31.0 | 27.0 | 286.3 | |

| M | 293 | 668.0 | 305.0 | 21.0 | 40.0 | 27.0 | 373.7 | |

| HE700 | AA | 150 | 670.0 | 300.0 | 13.0 | 17.0 | 27.0 | 190.9 |

| A | 204 | 600.0 | 300.0 | 14.5 | 27.0 | 27.0 | 260.5 | |

| B | 241 | 700.0 | 300.0 | 17.0 | 32.0 | 27.0 | 306.4 | |

| M | 301 | 716.0 | 304.0 | 21.0 | 40.0 | 27.0 | 383.0 | |

| HE800 | AA | 172 | 770.0 | 300.0 | 14.0 | 18.0 | 30.0 | 218.5 |

| A | 224 | 790.0 | 300.0 | 15.0 | 28.0 | 30.0 | 285.8 | |

| B | 262 | 800.0 | 300.0 | 17.5 | 33.0 | 30.0 | 334.2 | |

| M | 317 | 814.0 | 303.0 | 21.0 | 40.0 | 30.0 | 404.3 | |

| HE800 | AA | 198 | 870.0 | 300.0 | 15.0 | 20.0 | 30.0 | 252.2 |

| A | 252 | 800.0 | 300.0 | 16.0 | 30.0 | 30.0 | 320.5 | |

| B | 291 | 900.0 | 300.0 | 18.5 | 35.0 | 30.0 | 371.3 | |

| M | 333 | 910.0 | 302.0 | 21.0 | 40.0 | 30.0 | 423.6 | |

| HEB1000 | AA | 222 | 970.0 | 300.0 | 16.0 | 21.0 | 30.0 | 282.2 |

| A | 272 | 0.0 | 300.0 | 16.5 | 31.0 | 30.0 | 346.8 | |

| B | 314 | 1000.0 | 300.0 | 19.0 | 36.0 | 30.0 | 400.0 | |

| M | 349 | 1008 | 302.0 | 21.0 | 40.0 | 30.0 | 444.2 | |

ASTAAMAHA

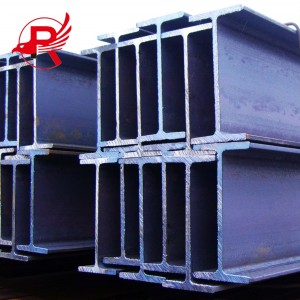

Qaybaha birta ee HEA, HEB, iyo HEM waa noocyada alwaaxyada birta ee heerka Yurub ee IPE (qaybta isgoyska ah ee qaabaysan ee I) oo si ballaaran loogu isticmaalo dhismaha iyo injineernimada qaab-dhismeedka. Waa kuwan astaamaha ugu muhiimsan ee nooc kasta:

Qaybta birta ee HEA (IPN):

Ballaca iyo dhumucda flange-ka weyn

Ku habboon qaab-dhismeedka leh culeysyo culus

Waxay bixisaa awood rar oo wanaagsan iyo xoog foorarsi

Qaybta birta HEB (IPB):

Ballaca flange-ka dhexdhexaadka ah iyo dhumucdiisuna

Noocyo badan leh, oo si caadi ah loogu isticmaalo dhismayaasha kala duwan

Waxay isku daraysaa xoogga iyo faa'iidooyinka fudud

Qaybta birta ee HEM:

Dhererka flange-ka weyn iyo ballaca cidhiidhiga ah

Waxay bixisaa xoog sare iyo awood culays-qaadis

Ku habboon qaab-dhismeedka culeysyo culus iyo cadaadis sare leh

ENH- Bir qaabaysan

Darajada: EN10034:1997 EN10163-3:2004

Faahfaahinta: HEA HEB iyo HEM

Heerka: EN

BAARITAANKA ALAABTA

Shuruudaha muhiimka ah ee lagu baarayo birta qaabka H waxaa ka mid ah dhinacyada soo socda:

Tayada Muuqaalka: Muuqaalka birta qaabka H waa inuu buuxiyaa heerarka khuseeya iyo shuruudaha macaamiisha. Dusha sare waa inay noqotaa mid siman oo siman, oo ka xor ah godad muuqda, xoqan, meelo miridhku ka baxo, iyo cillado kale.

Cabbirka Joomatari: Dhererka, ballaca, dhererka, dhumucda shabakadda, iyo dhumucda flange ee birta qaab-H ah waa inay u hoggaansamaan heerarka khuseeya iyo shuruudaha macaamiisha.

Toosnaanta: Toosnaanta birta qaabka H waa inay buuxisaa heerarka khuseeya iyo shuruudaha macaamiisha. Tan waxaa lagu xaqiijin karaa iyadoo la cabbirayo isbarbardhigga labada daraf ama la isticmaalayo cabbir toosan.

Tursion: Tursion-ka birta qaab-H ah waa inuu buuxiyaa heerarka khuseeya iyo shuruudaha macaamiisha. Tan waxaa lagu xaqiijin karaa iyadoo la cabbirayo toosanaanta dhinacyada ama la isticmaalayo tijaabiye torsion ah.

Kala Duwanaanta Miisaanka: Miisaanka birta qaabka H waa inuu buuxiyaa heerarka khuseeya iyo shuruudaha macaamiisha. Kala Duwanaanta Miisaanka waxaa lagu hubin karaa miisaan.

Qaab-dhismeedka Kiimikada: Haddii birta qaab-dhismeedka H u baahan tahay alxan ama habayn kale, qaab-dhismeedkeeda kiimikadu waa inay buuxisaa heerarka khuseeya iyo shuruudaha macaamiisha.

Sifooyinka Farsamada: Sifooyinka farsamada ee birta qaabka H waa inay buuxiyaan heerarka khuseeya iyo shuruudaha macaamiisha, oo ay ku jiraan xoogga jiidista, xoogga wax soo saarka, dheereynta, iwm.

Tijaabinta aan burburin: Haddii tijaabada aan burburin loo baahan yahay birta qaabaysan ee H, waa in lagu sameeyaa iyadoo la raacayo heerarka khuseeya iyo shuruudaha macaamiisha si loo hubiyo in tayadeeda gudaha ay buuxiso shuruudaha.

Baakadeynta iyo Calaamadaynta: Baakadeynta iyo calaamadaynta birta qaabka H waa inay u hoggaansantaa heerarka khuseeya iyo shuruudaha macaamiisha, taasoo sahlaysa rarista iyo kaydinta.

Marka la soo koobo, marka la baarayo birta qaabka H, dhammaan shuruudaha kor ku xusan waa in si buuxda loo tixgeliyaa si loo hubiyo in tayadu ay buuxiso heerarka khuseeya iyo shuruudaha macaamiisha, sidaas darteedna la siinayo dadka isticmaala alaabada birta qaabka H ee tayada sare leh.

CODSIGA

Iftiinka HEA, HEB, iyo HEMwaxay leeyihiin codsiyo kala duwan oo ku saabsan warshadaha dhismaha iyo injineernimada qaab-dhismeedka. Qaar ka mid ah isticmaalka caadiga ah waxaa ka mid ah:

- Mashruucyada Dhismaha: Qaybahan birta ah waxaa si caadi ah loogu isticmaalaa dhismaha dhismayaasha ganacsiga iyo warshadaha, iyagoo taageero siinaya dabaqyada, saqafyada, iyo dhismayaasha kale ee culeyska qaada.

Injineernimada Buundada: Waxaa loo isticmaalaa dhismaha buundooyinka, iyagoo taageeraya sagxadda buundada iyo qaybaha kale ee dhismaha.

Xarumaha Warshadaha: Qaybaha birta ee HEA, HEB, iyo HEM ayaa si weyn loogu isticmaalaa dhismaha dhismayaasha warshadaha sida bakhaarada, warshadaha, iyo xarumaha kaydinta.

Qaab-dhismeedka: Waxaa loo isticmaali karaa in lagu dhiso qaab-dhismeedka dhismayaasha waaweyn iyo mashaariicda kaabayaasha dhaqaalaha, iyadoo la siinayo taageero derbiyada, dahaarka, iyo walxaha kale ee dhismaha.

Taageerada Qalabka: Qaybahan birta ah waxaa loo isticmaali karaa in lagu taageero mashiinnada iyo qalabka culus ee deegaanno warshadeed oo kala duwan.

Mashruucyada Kaabayaasha Dhaqaalaha: Qaybaha birta ee HEA, HEB, iyo HEM ayaa sidoo kale loo isticmaalaa dhismaha mashaariicda kaabayaasha dhaqaalaha sida godadka dhulka hoostiisa mara, garoomada diyaaradaha, iyo warshadaha korontada.

Marka la soo koobo, qaybahan birta ah waxay door muhiim ah ka ciyaaraan mashaariicda dhismaha iyo injineernimada kala duwan, iyagoo bixiya taageero dhismeed oo adag oo la isku halleyn karo. Kala duwanaanshahooda, xooggooda, iyo awooddooda culeyska ayaa ka dhigaya agab aan laga maarmi karin dhismaha casriga ah iyo naqshadeynta kaabayaasha dhaqaalaha.

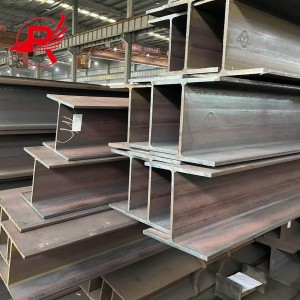

BAAKADAHA IYO GEYNTA

Baakadeynta iyo Ilaalinta

Baakad sax ah ayaa muhiim u ah hubinta tayada birta ASTM A36 ee qaabka H inta lagu jiro rarista iyo kaydinta: Isticmaal suuman/xariijimo bir ah oo xoog badan si aad si ammaan ah ugu xidho alwaaxyada birta si looga hortago beddelka iyo dhaawaca; Isticmaal agabyada u adkaysta cimilada sida balaastigga balaastikada ah ama maro aan biyuhu celin karin si aad uga ilaaliso qoyaanka iyo boodhka, adigoo ka hortagaya miridhku.

Soo rarista, Soo dejinta, iyo Sugidda

Si taxaddar leh u qabo alwaaxyada birta ah ee baakadaysan inta lagu jiro rarista iyo dejinta: Isticmaal qalabka kor u qaadista ee ku habboon sida fargeetooyinka ama wiishashka si aad u hubiso badbaadada iyo hufnaanta; Marka la raro, si siman u qaybi alwaaxyada birta ah oo si sax ah u hagaaji si looga hortago burburka dhismaha; Ka dib marka la raro, ku xidh xamuulka xadhko, silsilado, iwm., si loo hubiyo xasilloonida iyo ka hortagga wareejinta inta lagu jiro rarista. Soo koobiddan kooban waxay diiradda saareysaa hababka iyo shuruudaha muhiimka ah, taasoo sahlaysa in si dhakhso ah loo fahmo macluumaadka muhiimka ah. Haddii aad rabto inaad si dheeraad ah u fududeyso qayb kasta ama aad ku darto faahfaahin gaar ah (sida noocyada agabka ilaalinta), fadlan noo sheeg.

Su'aalaha Badiya La Weydiiyo

1. Sideen kaaga heli karaa xigasho?

Waad noo dhaafi kartaa farriin, waxaanan ka jawaabi doonnaa farriin kasta waqtigeeda.

2. Ma alaabta ku geyn doontaa waqtigii loogu talagalay?

Haa, waxaan ballan qaadaynaa inaan bixinno alaabada ugu tayada wanaagsan iyo gaarsiinta waqtigii loogu talagalay. Daacadnimadu waa mabda'a shirkaddayada.

3. Ma heli karaa muunado ka hor dalabka?

Haa, dabcan. Badanaa muunadahayagu waa bilaash, waxaan ku soo saari karnaa muunadahaaga ama sawirrada farsamada.

4. Waa maxay shuruudaha lacag bixintaada?

Muddada lacag bixinta ee caadiga ah waa 30% deebaaji, waxaana naga xiga B/L. EXW, FOB, CFR, iyo CIF.

5. Ma aqbashaa kormeerka dhinac saddexaad?

Haa runtii waan aqbalnaa.

6. Sideen ugu kalsoonahay shirkaddaada?

Waxaan ku takhasusnay ganacsiga birta sannado badan annagoo ah alaab-qeybiye dahab ah, xaruntiisuna waxay ku taal gobolka Tianjin, waanu soo dhaweyneynaa inaan si kasta u baarno.