Xaashida Birta Larsen ee Kulul ee Nooca PZ ee Tiirarka Birta ah ee Warshadda Qiimaha Jumlada ah

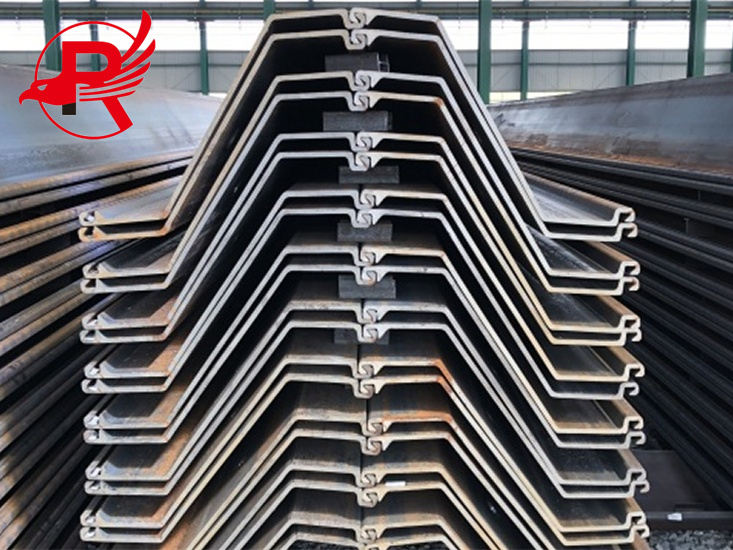

Habka wax soo saarka ee tuulmooyinka xaashida birta ah ee qaabka Z-qaabaysan ee kulul-la duubay badanaa waxaa ku jira tallaabooyinka soo socda:

Diyaarinta alaabta ceeriin: Marka hore, alaabta ceeriin waa in la diyaariyaa, badanaa waxaa loo isticmaalaa bir tayo sare leh sida alaabta ceeriin. Birahan waxay u baahan yihiin in la baaro oo la kala saaro si loo hubiyo inay buuxiyaan shuruudaha wax soo saarka.

Kuleylinta iyo rogrogidda: Alaabada ceeriin ah waa la kululeeyaa si loo gaarsiiyo heerkulka ku habboon ka dibna waxaa lagu wareejiyaa warshadda rogrogidda. Habkan, birta waxaa loo farsameeyaa qaab Z ah waxaana lagu wareejiyaa maro badan iyada oo loo marayo duubab kala duwan si loo hubiyo in qaabka iyo cabbirka badeecada kama dambaysta ah ay buuxiyaan shuruudaha caadiga ah.

Qaboojinta iyo qaabaynta: Ka dib marka la rogo, birta waxay u baahan tahay in la qaboojiyo si loo xasiliyo qaab-dhismeedkeeda iyo sifooyinkeeda. Isla mar ahaantaana, qaabaynta iyo jarista ayaa sidoo kale loo baahan yahay si loo hubiyo in badeecadu ay leedahay dusha siman iyo cabbirro sax ah.

Kormeerka iyo Baakaynta: Tuubooyinka xaashida birta ah ee la dhammeeyay waxay u baahan yihiin in la mariyo kormeer tayo sare leh, oo ay ku jiraan kormeerka tayada muuqaalka, leexashada cabbirka, halabuurka kiimikada, iwm. Alaabooyinka u qalma ayaa la xirxiri doonaa oo diyaar u ah in la soo raro.

Warshadda iyo gaadiidka: Badeecada ugu dambeysa waxaa lagu shubi doonaa gaariga xamuulka ah waxaana laga soo rari doonaa warshadda, iyadoo diyaar u ah in loo raro goobta macaamiisha si loo isticmaalo. Waa in taxaddar la sameeyaa si loo ilaaliyo badeecada inta lagu jiro rarista si looga fogaado waxyeello.

Qodobka kor ku xusan waa habka guud ee wax soo saarka ee tuulmooyinka birta ee qaabka Z. Habka wax soo saarka gaarka ah wuu kala duwanaan karaa iyadoo ku xiran soo saaraha iyo qalabka.

* U dir emaylka[emailka la ilaaliyo]si aad u hesho qiimeyn mashaariicdaada ah

| Heerka Birta | S275, S355, S390, S430, SY295, SY390, ASTM A690 |

| heerka caadiga ah | EN10248,EN10249,JIS5528,JIS5523,ASTM,GB/T 20933-2014 |

| Waqtiga keenista | 10 ~ 20 Maalmood |

| Shahaadooyinka | ISO9001, ISO14001, ISO18001, CE FPC |

| Dhererka | 6m-24m, 9m, 12m, 15m, 18m waa dherer dhoofineed oo caadi ah |

| Nooca | |

| Adeegga Habaynta | Feer, Jarid |

| Farsamada | Duub kulul, Duub qabow |

| Cabbirrada | PU400x100 PU400x125 PU400x150 PU400x170 PU500x200 PU500x225 PU600x130 PU600x180 PU600x210 |

| Noocyada isku xiran | Qufulada Larssen, quful qabow oo la duubay, quful kulul oo la duubay |

| Dhererka | 1-12 mitir ama dherer gaar ah |

| Codsiga | Daanta webiga, dekedda dekadda, xarumaha dawladda hoose, marinka tareenka magaalooyinka, xoojinta dhulgariirka, dekedda buundada, aasaaska sita, dhulka hoostiisa garaash, godka aasaaska, derbiga ilaalinta waddooyinka iyo shaqooyin ku meel gaar ah. |

* U dir emaylka[emailka la ilaaliyo]si aad u hesho qiimeyn mashaariicdaada ah

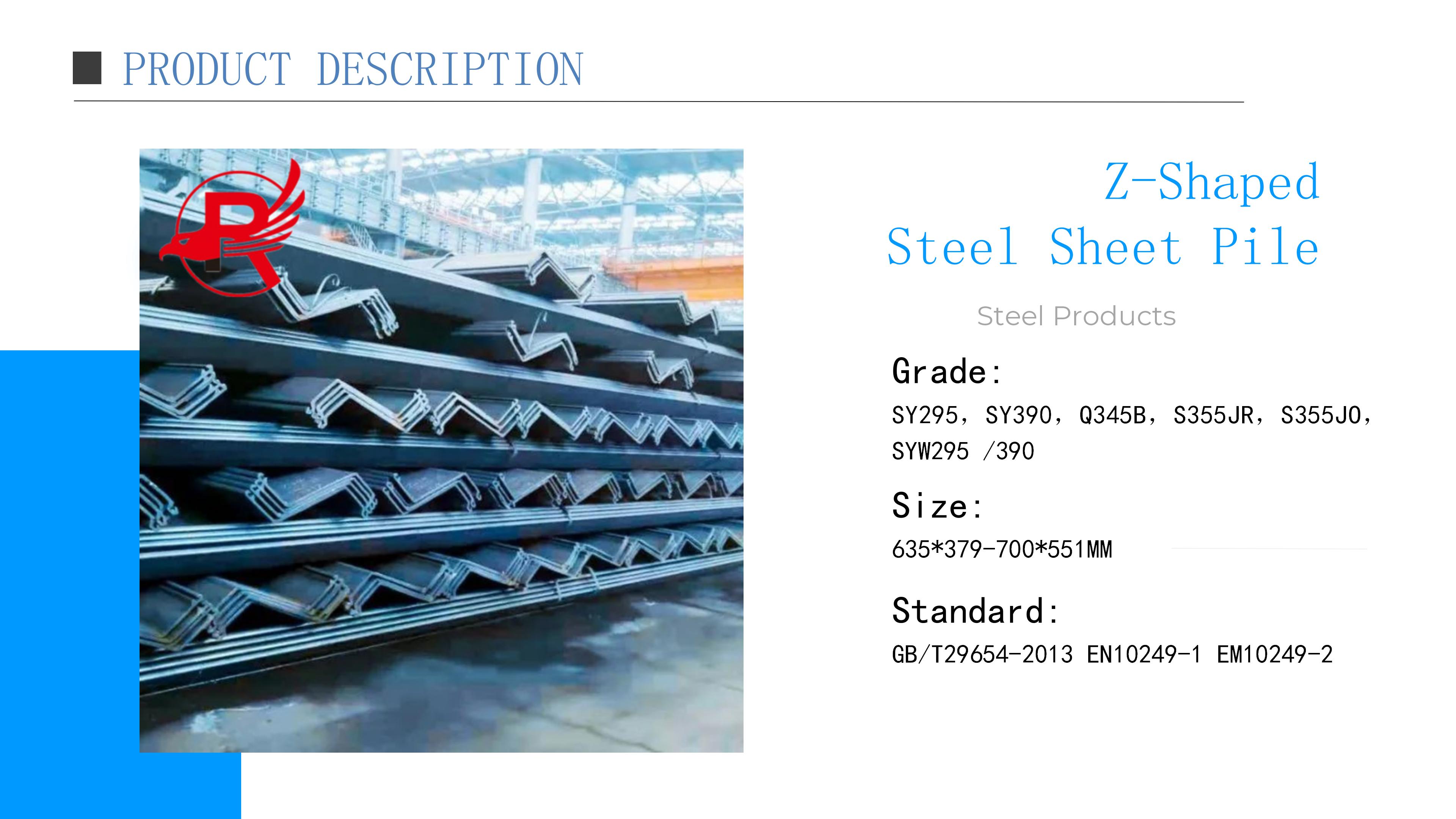

Dhererka (H) eetuulmo xaashi zBadanaa waxay u dhaxaysaa 200mm ilaa 600mm.

Ballaca (B) ee tuulmooyinka birta ah ee qaabka Z-ga ah ee Q235b badanaa waxay u dhexeeyaan 60mm ilaa 210mm.

Dhumucda (t) ee tuulmooyinka xaashida birta ah ee qaabka Z-ga badanaa waxay u dhaxaysaa 6mm ilaa 20mm.

| Qaybta | Ballaca | Dhererka | Dhumucda | Aagga Qaybaha Kala Duwan | Miisaanka | Modulus Qaybta Laablaaban | Daqiiqadda Inertia | Aagga dahaarka (labada dhinacba tuulmo kasta) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Shabakadda (tw) | Tuul kasta | Derbi kasta | |||||

| mm | mm | mm | mm | cm2/m | kg/m | kg/m2 | cm3/m | cm4/m | m2/m | |

| Nooca II | 400 | 200 | 10.5 | - | 152.9 | 48 | 120 | 874 | 8,740 | 1.33 |

| Nooca III | 400 | 250 | 13 | - | 191.1 | 60 | 150 | 1,340 | 16,800 | 1.44 |

| Nooca IIIA | 400 | 300 | 13.1 | - | 186 | 58.4 | 146 | 1,520 | 22,800 | 1.44 |

| Nooca IV | 400 | 340 | 15.5 | - | 242 | 76.1 | 190 | 2,270 | 38,600 | 1.61 |

| Nooca VL | 500 | 400 | 24.3 | - | 267.5 | 105 | 210 | 3,150 | 63,000 | 1.75 |

| Nooca IIw | 600 | 260 | 10.3 | - | 131.2 | 61.8 | 103 | 1,000 | 13,000 | 1.77 |

| Nooca IIIw | 600 | 360 | 13.4 | - | 173.2 | 81.6 | 136 | 1,800 | 32,400 | 1.9 |

| Nooca IVw | 600 | 420 | 18 | - | 225.5 | 106 | 177 | 2,700 | 56,700 | 1.99 |

| Nooca VIL | 500 | 450 | 27.6 | - | 305.7 | 120 | 240 | 3,820 | 86,000 | 1.82 |

Kala duwanaanshaha Qaybta Modulus

1100-5000cm3/m

Kala duwanaanshaha Ballaca (hal)

580-800mm

Kala duwanaanshaha dhumucda

5-16mm

Heerarka Wax-soo-saarka

BS EN 10249 Qaybta 1 & 2

Darajooyinka Birta

SY295, SY390 & S355GP ee Nooca II ilaa Nooca VIL

S240GP, S275GP, S355GP & S390 ee loogu talagalay VL506A ilaa VL606K

Dhererka

Ugu badnaan 27.0m

Dhererka Kaydka Caadiga ah ee 6m, 9m, 12m, iyo 15m

Ikhtiyaarada Bixinta

Keli ah ama Lammaane

Lammaane, dabacsan, alxan ama qallafsan

Godka Qaadista

Weel ahaan (11.8m ama ka yar) ama Qaybo badan oo lagu shubo

Dahaarka Ilaalinta Daxalka

ASTAAMAHA

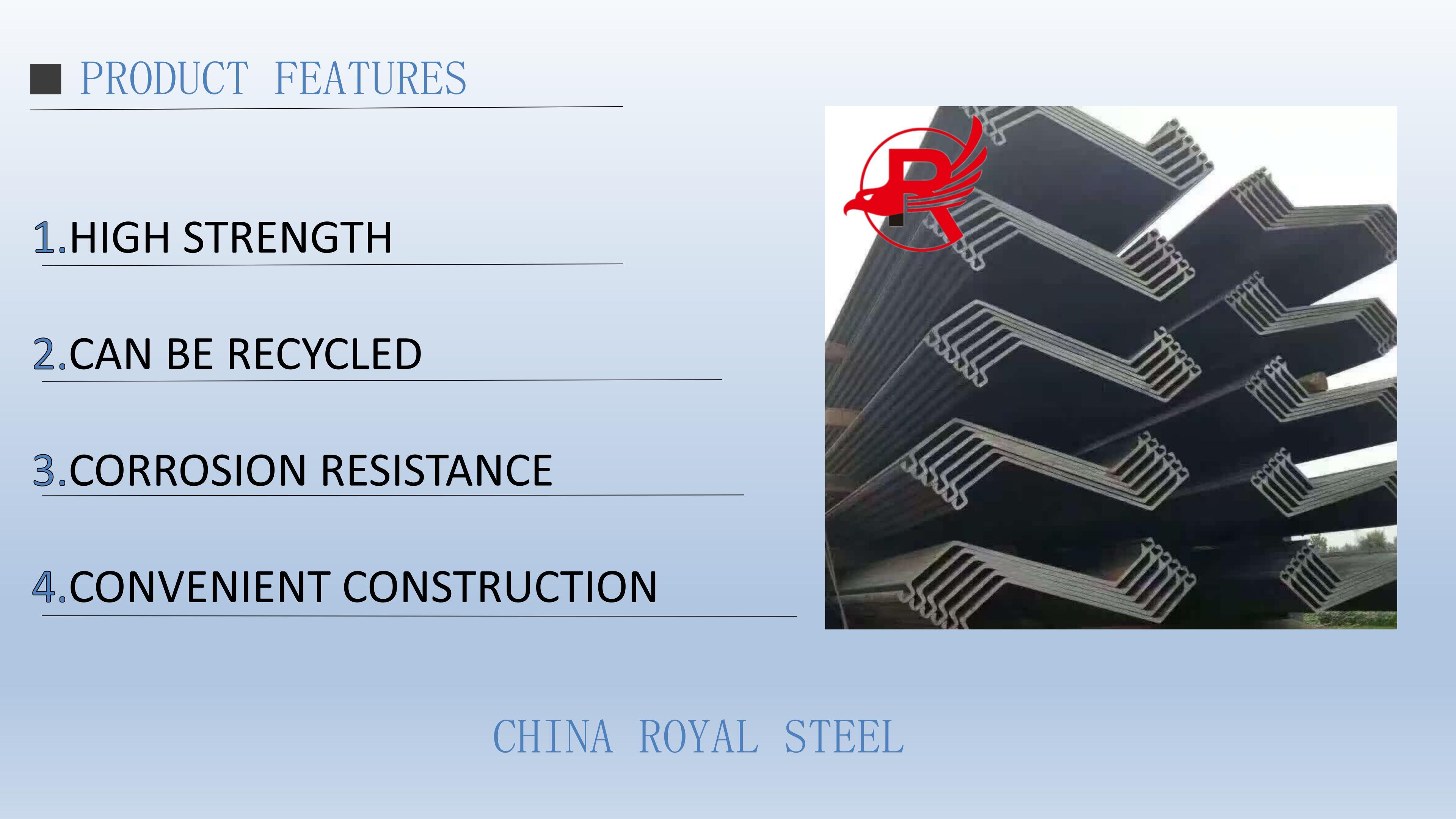

Tuulmo xaashi bir ahWaxaa si weyn loogu isticmaalaa injineernimada madaniga ah, inta badan waxaa loo isticmaalaa dhinacyada soo socda:

1. Dhismaha tunnelka iyo tareenka dhulka hoostiisa mara: Dhismaha tunnelka iyo tareenka dhulka hoostiisa mara, waxaa loo baahan yahay tuulmooyin bir ah si loo taageero loona xoojiyo dhismayaasha carrada iyo dhismaha.

2. Dhismaha derbiga oo la ilaaliyo: tuulmooyinka birta ah ee looxa ah ayaa loo isticmaali karaa dhismaha derbiyada lagu hayo si loo taageero loona xoojiyo ciidda.

3. Daaweynta Wabiga iyo Kanaalka: Inta lagu guda jiro daaweynta wabiga iyo kanaalada, waxaa loo baahan yahay tuulmooyin bir ah si loo xoojiyo sariirta wabiga loona hortago in sibidhka la geliyo.

4. Injineernimada Badda: Tuubooyinka xaashida birta ah waxaa loo isticmaali karaa injineeriyadda badda, sida taageerada iyo xoojinta dhuumaha badda hoosteeda.

5. Dhismaha Dekedda: Dhismaha Dekedda, waxaa loo baahan yahay tuulmooyin bir ah si loo dhiso kaabayaasha dekedaha loona taageero dhismayaasha dekedda.

CODSIGA

Tuulmooyin xaashi ahwaa agabyada kaabayaasha dhaqaalaha kuwaas oo ku dhejiya xaashiyo bir ah oo waaweyn ciidda si ay u sameeyaan nidaam qaab-dhismeed. Noocyada xaashida birta ee caadiga ah waxaa ka mid ah xaashida birta ee looxa ah, xaashida birta ee la xiro, xaashida birta ee la isku daray iyo wixii la mid ah. Marka la geliyo ciidda, xaashida birta waxay ciyaari kartaa doorka taageerada dhinaca, qaybinta lakabka dhexdooda, xidhitaanka durugsan, qufulka joojinta iyo wixii la mid ah

BAAKADAHA IYO GEYNTA

Gaadiidka weelasha waa hab caadi ah oo lagu qaado tuulmooyinka xaashida birta ah, kaas oo ku habboon kuwa yaryar.tuulmo bir ah oo bir ahWaqtigan xaadirka ah, shirkado badan ayaa adeegsada habka dhoofinta weelasha ganacsiga caalamiga ah ee tuulmooyinka birta, taas oo ah mid dhaqaale ahaan iyo hufnaan leh, oo aan saameyn ku yeelan cimilada, xaaladaha waddooyinka iyo arrimo kale.

AWOODDA SHIRKADDA

Lagu sameeyay Shiinaha, adeeg heer sare ah, tayo casri ah, caan ka ah adduunka

1. Saamaynta miisaanka: Shirkaddayadu waxay leedahay silsilad sahay oo weyn iyo warshad bir ah oo weyn, iyadoo gaadhaysa saameyn baaxad leh oo ku saabsan gaadiidka iyo soo iibsiga, waxayna noqonaysaa shirkad bir ah oo isku daraysa wax soo saarka iyo adeegyada.

2. Kala duwanaanshaha badeecadaha: Kala duwanaanshaha badeecadaha, bir kasta oo aad rabto waxaa naga iibsan kartaa, oo inta badan ku hawlan qaab-dhismeedka birta, biraha birta ah, biraha xaashida birta ah, biraha sawir-qaadista, birta kanaalka, biraha silikoonka iyo alaabada kale, taas oo ka dhigaysa mid dabacsan. Dooro nooca badeecadaha la rabo si aad u buuxiso baahiyaha kala duwan.

3. Sahayda deggan: In la helo khad wax soo saar oo deggan iyo silsilad sahay ayaa bixin karta sahay lagu kalsoonaan karo. Tani waxay si gaar ah muhiim ugu tahay iibsadayaasha u baahan tiro badan oo bir ah.

4. Saamaynta summada: Waxay leedahay saameyn summadeed oo sare iyo suuq ballaaran

5. Adeeg: Shirkad bir ah oo weyn oo isku daraysa habaynta, gaadiidka iyo wax soo saarka

6. Qiimaha tartanka: qiimo macquul ah

* U dir emaylka[emailka la ilaaliyo]si aad u hesho qiimeyn mashaariicdaada ah

HABKA BOOQASHADA MACMIILKA

Marka macaamiil uu rabo inuu booqdo badeeco, tallaabooyinka soo socda ayaa badanaa la diyaarin karaa:

Ballan samee si aad u booqato: Macaamiishu waxay la xiriiri karaan soo saaraha ama wakiilka iibka kahor si ay u ballansadaan waqtiga iyo goobta ay ku booqanayaan badeecada.

Diyaari safar hagitaan leh: U diyaari xirfadlayaal ama wakiillo iib ah hagayaal dalxiis si ay macaamiisha u tusaan habka wax soo saarka, tignoolajiyada iyo habka xakamaynta tayada ee badeecada.

Soo bandhig alaabada: Inta booqashada lagu jiro, macaamiisha u soo bandhig alaabada marxalado kala duwan si macaamiishu u fahmaan habka wax soo saarka iyo heerarka tayada ee badeecadaha.

Ka jawaab su'aalaha: Inta booqashada lagu jiro, macaamiishu waxay qabi karaan su'aalo kala duwan, hagaha dalxiiska ama wakiilka iibka waa inuu si dulqaad leh uga jawaabaa oo uu bixiyaa macluumaad farsamo iyo tayo leh oo khuseeya.

Bixi muunado: Haddii ay suurtogal tahay, muunado alaab ah ayaa la siin karaa macaamiisha si macaamiishu si qoto dheer u fahmaan tayada iyo astaamaha badeecada.

La socosho: Booqashada ka dib, si dhakhso leh ula soco jawaab celinta macaamiisha waxayna u baahan tahay inay macaamiisha siiso taageero iyo adeegyo dheeraad ah.