Gariiradda Birta Gariiradda leh ee Kulul Q195 Q215 St37 S235jr S355jr Ss400 Birta Gariiradda Sare ee Tayada ugu sareysa

Faahfaahinta Alaabta

| Magaca Alaabta | Hoselling Tayada ugu Fiican Qadar badanGariiradda Birta ee Hot Rolled |

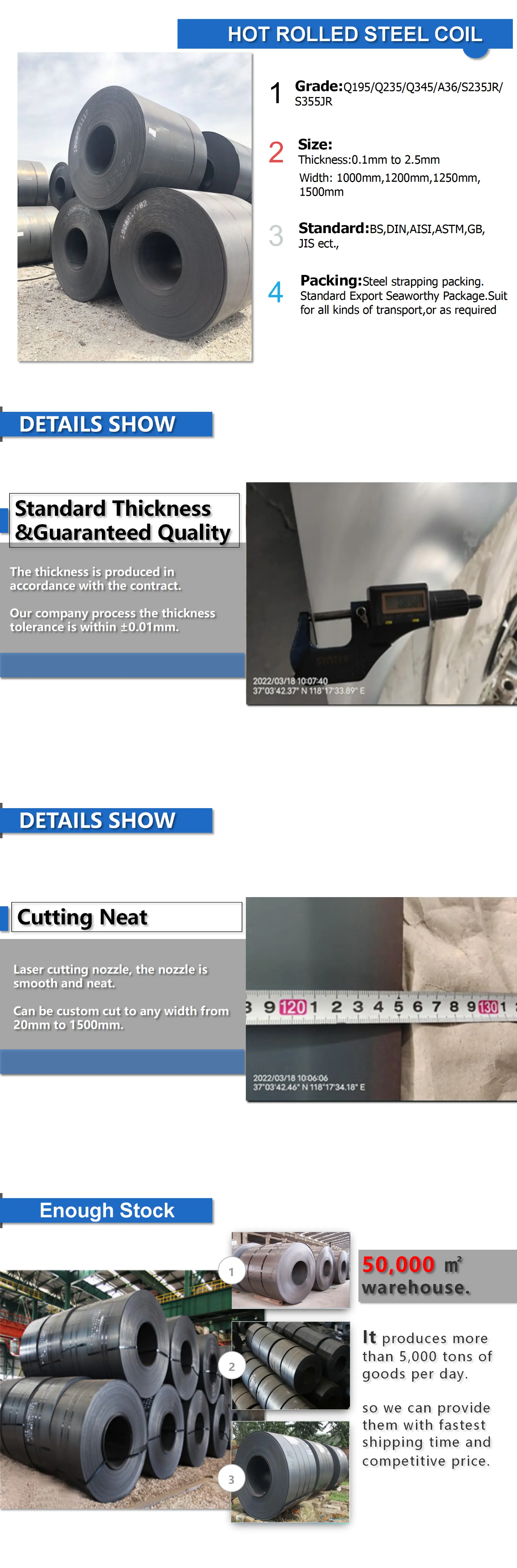

| Qalab | Q195/Q235/Q345/A36/S235JR/S355JR |

| Dhumucda | 1.5mm ~ 24mm |

| Cabbirka | 3x1219mm 3.5x1500mm 4x1600mm 4.5x2438mm waa la habeeyay |

| Heerka | ASTM A53-2007, ASTM A671-2006, ASTM A252-1998, ASTM A450-1996, ASME B36.10M-2004, ASTM A523-1996, BS 1387, BS EN10296, BS |

| 6323, BS 6363, BS EN10219, GB/T 3091-2001, GB/T 13793-1992, GB/T9711 | |

| Darajo | A53-A369, Q195-Q345, ST35-ST52 |

| Fasalka A, Fasalka B, Fasalka C | |

| Farsamada | Kulul duuban |

| Baakad | Xidhmo, ama dhammaan noocyada kala duwan ee midabada PVC ama sida shuruudahaaga |

| Dhuumaha Dhammaad | Dhammaadka bannaan/Beveled, oo lagu ilaaliyo koofiyadaha caagagga ah ee labada daraf, googooyn, jeexjeexan, xadhig iyo isku xidhka, iwm. |

| MOQ | 1 tan, qiimaha tirada badan ayaa hoos u dhici doona |

| Daaweynta Dusha sare | 1. Mill dhammeeyey / galvanized / ahama |

| 2. PVC, rinjiyeynta madow iyo midabka | |

| 3. Saliid hufan,saliid ka hortagga miridhku | |

| 4. Marka loo eego shuruudaha macaamiisha | |

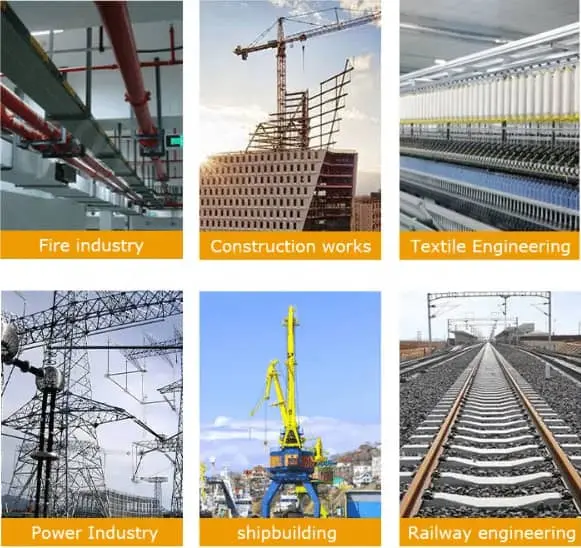

| Codsiga Alaabta | 1. Wax-soo-saarka qaab-dhismeedka dhismaha. |

| 2. Mashiinnada wax lagu qaado, | |

| 3. injineernimada, | |

| 4. Mashiinada beeraha iyo dhismaha. | |

| Asal ahaan | Tianjin Shiinaha |

| Shahaadooyinka | ISO9001-2008,SGS.BV,TUV |

| Waqtiga Bixinta | Caadiyan 10-15 maalmood gudahooda ka dib markii la helo lacag hormaris ah |

Codsiga ugu muhiimsan

1.Fluid / Gaaska gaaska, Qaab dhismeedka birta, Dhismaha;

2.ROYAL GROUP ERW / welded tuubooyinka birta kaarboon wareeg ah, kuwaas oo leh tayada ugu sarreeya iyo awoodda sahayda xooggan ayaa si weyn loogu isticmaalaa qaab-dhismeedka Birta iyo Dhismaha.

Fiiro gaar ah:

1.Saamaynta bilaashka ah, 100% hubinta tayada iibka kadib, Taageer hab kasta oo lacag bixin ah;

2.Dhammaan qeexitaannada kale ee tuubooyinka birta kaarboonka wareega ayaa la heli karaa iyadoo loo eegayo baahidaada (OEM & ODM)! Qiimaha warshadda waxaad ka heli doontaa ROYAL GROUP.

Shaxda cabbirka

| Dhumucda (mm) | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | habaysan |

| Ballaca (mm) | 800 | 900 | 950 | 1000 | 1219 | 1000 | habaysan |

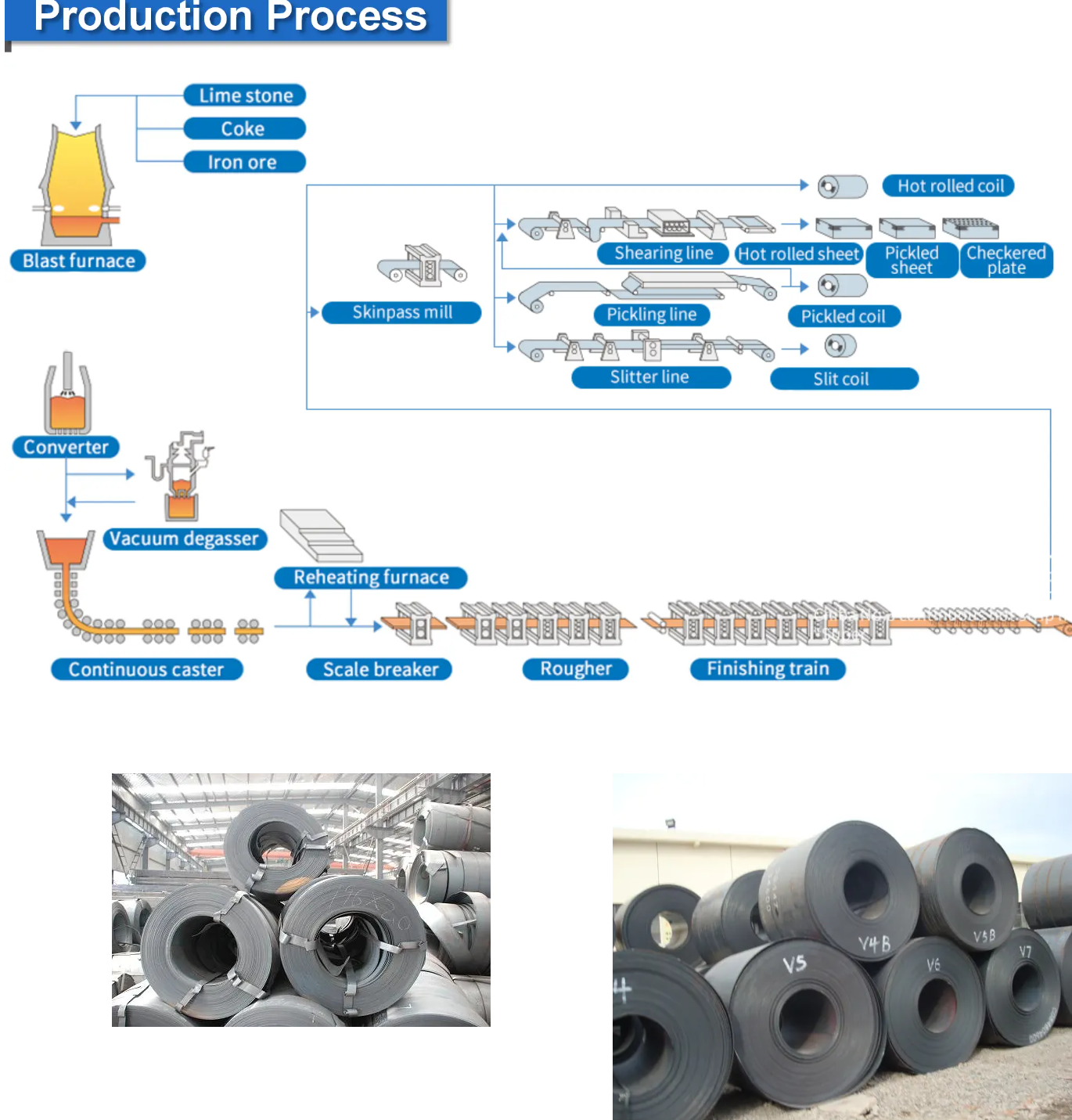

Habka wax soo saarka

Habka wax soo saarka ee kululayntagariiradda birta ahwaa isku xirka muhiimka ah ee wax soo saarka birta. Waxay inta badan ka samaysaa billet billet qaab saxan loo baahan yahay iyada oo loo marayo rogrogis heerkul sare ah. Kuwa soo socda ayaa ah talaabooyinkeeda asaasiga ah:

Diyaarinta Qalabka Ceyriinka

Dabaqyada si joogto ah loo shubay ama ubaxa ayaa loo isticmaalaa sidii alaab cayriin ah, sida caadiga ah dhumucdiisu tahay 150-300 mm.

Dusha dusha sare waa la nadiifiyaa (tusaale, nadiifinta ololka ama shiidida farsamada) si meesha looga saaro miisaanka iyo cilladaha si loo hubiyo tayada duubista.

Kululaynta

Daboolka waxaa lagu quudiyaa foornada alwaax-socod waxaana lagu kululeeyaa 1100-1300 ° C si loo gaaro heerkulka hagaajinta iyo hagaajinta caagga.

Wakhtiga kulaylka iyo isku midnimada heerkulka waa la xakameeyaa si looga fogaado kulaylka ama kulaylka hoostiisa.

Qalafsanaan

Salaxda waxaa lagu dhimay dhumucda 30-50 mm ee warshadda roughing rogeysa (tusaale, laba-ama afar-mareen-sare) si loo sameeyo bar dhexdhexaad ah.

Ka bac kasta oo rogaal celis ah ka dib, nadiifinta biyaha cadaadisku sareeyo ayaa laga yaabaa in la sameeyo si loo saaro lakabka oksaydhka oogada.

Dhamaystirka

Barka dhexe waxa uu galaa mishiinka wax lagu dhammeeyo (badanaa waxa uu ka kooban yahay lix ama todobo afar-ama lix-dhar-sare ah) halkaas oo si tartiib tartiib ah hoos loogu dhigo dhumucda bartilmaameedka (tusaale, 1.2-25 mm) iyada oo loo marayo duubid joogto ah. Xakamaynta Cabbirka Tooska ah (AGC) iyo nidaamka xakamaynta qaabka ayaa loo isticmaalaa si loo hubiyo saxnaanta cabbirka iyo fidsanaanta.

Inta lagu jiro habka duubista, duubku waxay u baahan yihiin qaboojin iyo saliid si looga hortago qallafsanaanta kulaylka iyo xirashada.

Qaboojin

Nidaamka qaboojinta laminar ayaa loo isticmaalaa in si degdeg ah loo qaboojiyo fiilada birta laga bilaabo heerkulka wareega ugu dambeeya (qiyaastii 800 ° C) ilaa heerkulka qolka iyada oo la xakameynayo mugga biyaha iyo heerka qaboojinta (tusaale, 30-50C/sekand).

Habka qaboojinta waxay si toos ah u saamaysaa qaab-dhismeedka yar yar (tusaale, saamiga ferrite iyo pearlite) iyo sifooyinka farsamada ee gariiradda birta.

Gariiradda

Xarigga birta ah waxaa lagu duuduubay gariirad iyadoo la isticmaalayo duubo qanjaruufo ah iyo gariiriye. Xiisadda waxaa lagu xakameynayaa 100-500 N/mm² si loo hubiyo qaab gariirad adag oo aan lahayn gariiro dabacsan.

Heerkulka gariiradda ayaa caadi ahaan la kantaroolaa inta u dhaxaysa 550-700 ° C si kor loogu qaado waxqabadka.

Processing ka dib

Daaweynta dusha sare: Qaadista si looga saaro miisaanka oksaydhka, ama dahaarka sida galvanizing ama aluminium.

Baakadaha iyo Gaadiidka

Caadi ahaan xirmo qaawan

Gaadiidka:Degdegga (Garitaanka Tusaalaha), Hawada, Tareenka, Dhulka, Maraakiibta Badda (FCL ama LCL ama Bulk)

FAQ

S: Ma saaraha ua?

J: Haa, waxaanu nahay soo-saare. Waxaan leenahay warshad noo gaar ah oo ku taal magaalada Tianjin, Shiinaha.

S: Ma heli karaa amar tijaabo ah oo kaliya dhowr tan?

J: Dabcan. Waxa aanu kuugu soo rari karnaa xamuulka adeega LCL.(Culshada weelka oo ka yar)

S: Haddii muunad bilaash ah?

J: Tusaalaha bilaashka ah, laakiin iibsadaha ayaa bixiya xamuulka.

S: Ma waxaad tahay alaab-qeybiye dahab ah oo ma samaysaa dammaanad ganacsi?

J: Anaga waxaanu todobada sano nahay alaab-qeybiye dahab ah waxaanan aqbalnaa dammaanad ganacsi.