Badeecadaha

-

Birta Struts-ka ee Galvanized Slotted C Channel Birta Strut Channel

Marka ay timaado dhisidda dhismayaal adag oo la isku halleyn karo, xulashada qalabka dhismaha ee saxda ah waa muhiim. Xulashooyinka badan ee la heli karo, C-Channel Structural Steel waxay u taagan tahay doorasho badan oo caan ah. Noocyada kala duwan ee C Purlins, waxaan si gaar ah diiradda u saari doonnaa nooca galvanized sababtoo ah cimri dhererkiisa iyo xooggiisa gaarka ah. Shaqada ugu weyn eebirta kanaalka c stratch waa in la hagaajiyobirta kanaalka cmodules-yo kala duwan oo ku kala duwanbirta kanaalka cXaaladaha isticmaalka saldhigga korontada sida saqafyada, dhulka, iyo dusha sare ee biyaha, si loo hubiyo in muraayadaha qorraxda lagu hagaajin karo meesha ay ku jiraan oo ay u adkeysan karaan cufisjiidadka iyo cadaadiska dabaysha. Waxay sidoo kale kaa caawin kartaa hagaajinta xagasha muraayadaha qorraxda si ay ula qabsadaan shucaaca qorraxda ee kala duwan iyo hagaajinta hufnaanta soo saarista tamarta qorraxda.

-

Tayada Alaab-qeybiyaha Birta Warshadaha ee la galvanized Strut iyo Birta Kanaalka Tayada leh

Marka ay timaado dhisidda dhismayaal adag oo la isku halleyn karo, xulashada agabka dhismaha ee saxda ah waa muhiim. Xulashooyinka badan ee la heli karo waxaa ka mid ahBirta Qaab-dhismeedka C-ChannelWaxay u muuqataa mid doorasho badan leh oo caan ah. IA Noocyada kala duwan ee C Purlins, waxaan si gaar ah diiradda u saari doonnaa nooca galvanized-ka ah sababtoo ah adkeysigeeda iyo xooggeeda gaarka ah.

-

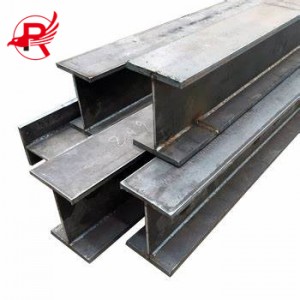

Kanaalka Laba-geesoodka ah | Kanaalka Strut ee Jaban | C Purlin oo Kulul lagu shubay

Birta Qaab-dhismeedka C ChannelBadanaa waxay ka samaysan yihiin bir qaabaysan oo U-qaabaysan ama bir qaabaysan oo C-qaabaysan oo laga sameeyay zinc, aluminium iyo magnesium iyo agabyo taageero iyo isku xidh. Naqshadani waxay ka dhigaysaa biraha mid fudud oo aan ahayn oo keliya in la qaado, laakiin sidoo kale si fudud loo isugu keeni karo, si fudud loo ilaalin karo, cimri dheer oo adeeg ah, iyo kharash dhaqaale oo hooseeya. Intaa waxaa dheer, biraha sawir-qaadista waxaa sidoo kale loo qaybin karaa biraha go'an iyo biraha raadraaca. Biraha go'an waxaa loo sii qaybiyaa biraha go'an ee caadiga ah iyo biraha la hagaajin karo ee go'an. Jihaynta qaybaha waxaa gacanta lagu hagaajin karaa iyadoo loo eegayo isbeddellada iftiinka xilliyada kala duwan.

-

Qalabka Tuubada Mareykanka ee La Qabsado Soo-saare Shiinees ah oo lagu hagaajin karo Qalabka Birta Lawska ee Laatka ah ee Lacagta ah

Qalabka tuubada lagu xidho waa nooca ugu gaarka ah ee lagu xidho. Inta badan waxaa loo isticmaalaa hagaajinta iyo xidhitaanka dhuumaha, sida isku xirka dhuumaha iyo hagaajinta dhuumaha derbiyada. Alaabooyinkani waa kuwo miisaankoodu fudud yahay, xasilloonidoodu xooggan tahay, qaab-dhismeedkoodu fudud yahay oo si fudud loo shaqayn karo. Ku habboon warshado badan oo dhismaha ah.

-

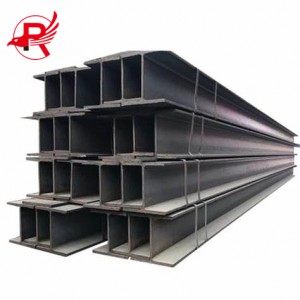

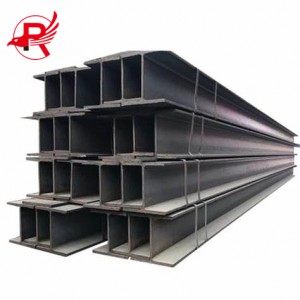

Alwaaxyo Balaadhan oo Flange ah | Alwaaxyo Bir ah oo A992 iyo A36 ah oo leh Cabbirro Kala Duwan

Alwaaxyo ballaaran oo flange ah, oo ay ku jiraan W4x13, W30x132, iyo W14x82 oo ku jira birta A992 iyo A36. Soo hel xulasho ballaaran oo ahQoryaha Wbaahiyahaaga qaab-dhismeedka.

-

ASTM Bir qaab H ah W4x13, W30x132, W14x82 | Bir A36 H Bead

ASTM Birta Qaab-H ahcabbirro iyo agab kala duwan oo ay ku jiraan birta A992 iyo A36. Soo hel alwaax w, w4x13, w30x132, w14x82 iyo waxyaabo kaloo badan oo w-beams ah. Ka dukaameyso hadda!

-

Kanaalka laba-geesoodka ah ee Unistrut-ka ah ee birta khafiifka ah ee Unistrut-ka ah ee birta galvanized-ka ah

Kanaallada taageerada birta ee la galvanizedwaxaa badanaa loo isticmaalaa in lagu taageero, lagu qaabeeyo loona sugo qaybo kala duwan oo dhismaha iyo warshadaha ah. Kanaaladan waxaa laga sameeyay bir galvanized ah waxaana lagu dahaadhay lakab zinc ah si looga hortago daxalka loona xoojiyo cimri dhererka. Kanaalada boostada waxaa loogu talagalay godad iyo godad si ay si fudud ugu xidhaan qalabka iyo agabka, taasoo u oggolaanaysa rakibaad dabacsan oo la habeyn karo. Waxaa si weyn loogu isticmaalaa codsiyada korontada, farsamada iyo qaab-dhismeedka si loo taageero tuubooyinka, tuubooyinka, fiilooyinka iyo qalabka kale. Dahaarka galvanized wuxuu bixiyaa ilaalin dheeraad ah oo ka dhan ah xaaladaha deegaanka ee adag, taasoo ka dhigaysa kanaaladan tiirarka ah kuwo ku habboon isticmaalka gudaha iyo dibadda labadaba.

-

Alwaaxyada Flange-ka ee ballaaran ee ASTM Steel-Qaabka H-qaabeeya

ASTM Birta Qaab-H ahoo sidoo kale loo yaqaan alwaaxyada W, waxay ku yimaadaan cabbirro kala duwan sida W4x13, W30x132, iyo W14x82. Laga sameeyay bir A992 ama A36, alwaaxyadani waxay ku habboon yihiin mashaariic badan oo dhisme.

-

Qiimaha Soo-saaraha Shiinaha ee Unistrut Strut C Channel Prices Hot Dipped Galvanized Strut Channel

Kanaalka CKanaallada Taageerada waxaa badanaa loo isticmaalaa dhismaha iyo codsiyada warshadaha si loo taageero fiilooyinka, tuubooyinka, iyo qalabka kale. Kanaalladani waxay ka samaysan yihiin bir (badanaa bir ama aluminium) waxaana loogu talagalay qayb iskutallaab ah oo qaab C ah si loogu daro xoog iyo adkaansho. Naqshadeyntu waxay u oggolaanaysaa rakibid fudud iyo dabacsanaan ku rakibidda qaybo kala duwan. Kanaallada strut-ka ee C-channel waxaa badanaa loo isticmaalaa iyadoo lagu darayo qalabka iyo qalabka si loo abuuro qaabab taageero oo gaar ah oo loogu talagalay noocyada kala duwan ee qalabka iyo nidaamyada.

-

Baarka naxaasta ah C28000 C27400 C26800 Usha naxaasta ah ee CuZn40 Baarka Wareega ah ee naxaasta ah

Usha naxaasta ah waa nooc ka mid ah usha farsamaynta birta aan birta ahayn oo leh waxqabad wanaagsan oo wax lagu farsameeyo iyo koronto-qaadis sare. Inta badan waxaa loo qaybiyaa usha naxaasta ah (daawaha naxaasta-zinc, oo ka jaban) iyo usha naxaasta cas (ka kooban naxaasta oo ka sarreysa).

-

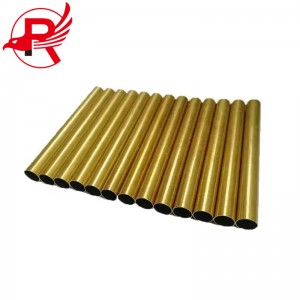

Tuubada Naxaasta ah Tuubada Naxaasta ah ee Hollow H62 C28000 C44300 C68700 Tuubada Naxaasta ah

Tuubo naxaas ah, Nooc ka mid ah tuubooyinka birta aan birta ahayn, waa tuubo aan sinayn oo la riixay oo la jiiday. Tuubooyinka naxaasta ah waa kuwo xooggan oo u adkaysta daxalka, taasoo ka dhigaysa doorashada koowaad ee qandaraaslayaasha casriga ah ay ku rakibaan tuubooyinka biyaha, tuubooyinka kululaynta iyo qaboojinta dhammaan dhismayaasha ganacsiga ee la deggan yahay. Tuubooyinka naxaasta ah waa tuubooyinka biyaha ugu fiican.

-

Xarig Naxaas ah 0.5mm CuZn30 H70 C2600 Xarig Naxaas ah oo Naxaas ah / Xabag Naxaas ah / Xarig Naxaas ah

Naxaasku wuxuu leeyahay gudbin koronto oo wanaagsan, gudbin kuleyl, dabacsanaan, soo jiidasho qoto dheer iyo iska caabin daxaleed.

Gudbinta kulaylka ayaa ah tan labaad oo keliya marka loo eego lacagta waxaana si weyn loogu isticmaalaa sameynta qalabka korontada iyo kan kulaylka gudbiya.

Jawiga, biyaha badda iyo qaar ka mid ah asiidhyada aan oksaydhaynta lahayn (asiidh hydrochloric ah, asiidh sulfuric ah oo khafiif ah), alkalis, xalalka milixda iyo noocyo kala duwan

Waxay leedahay iska caabin wanaagsan oo daxalka ah oo ku jirta asiidhyada dabiiciga ah (acetic acid, citric acid) waxaana loo isticmaalaa warshadaha kiimikada.